Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

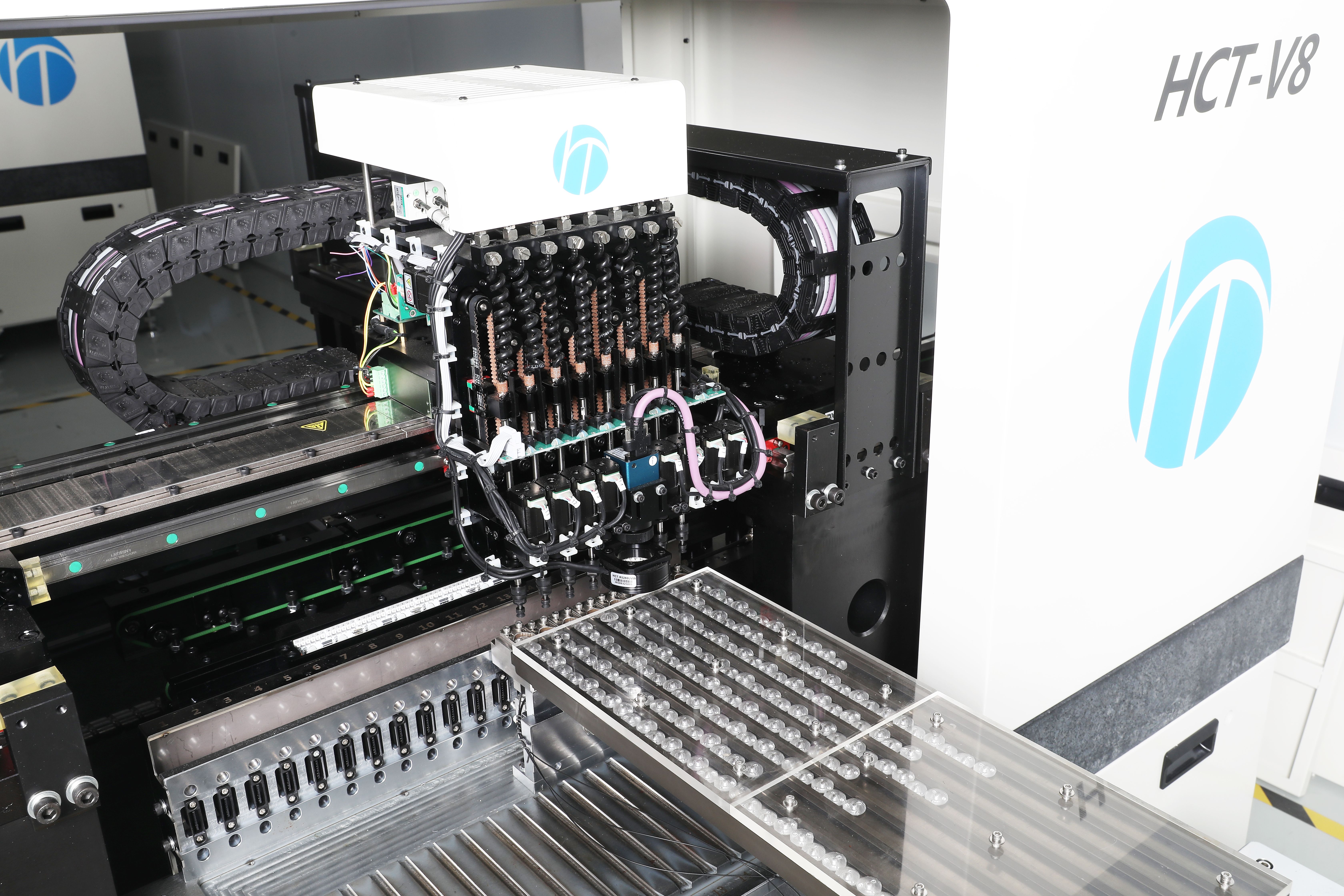

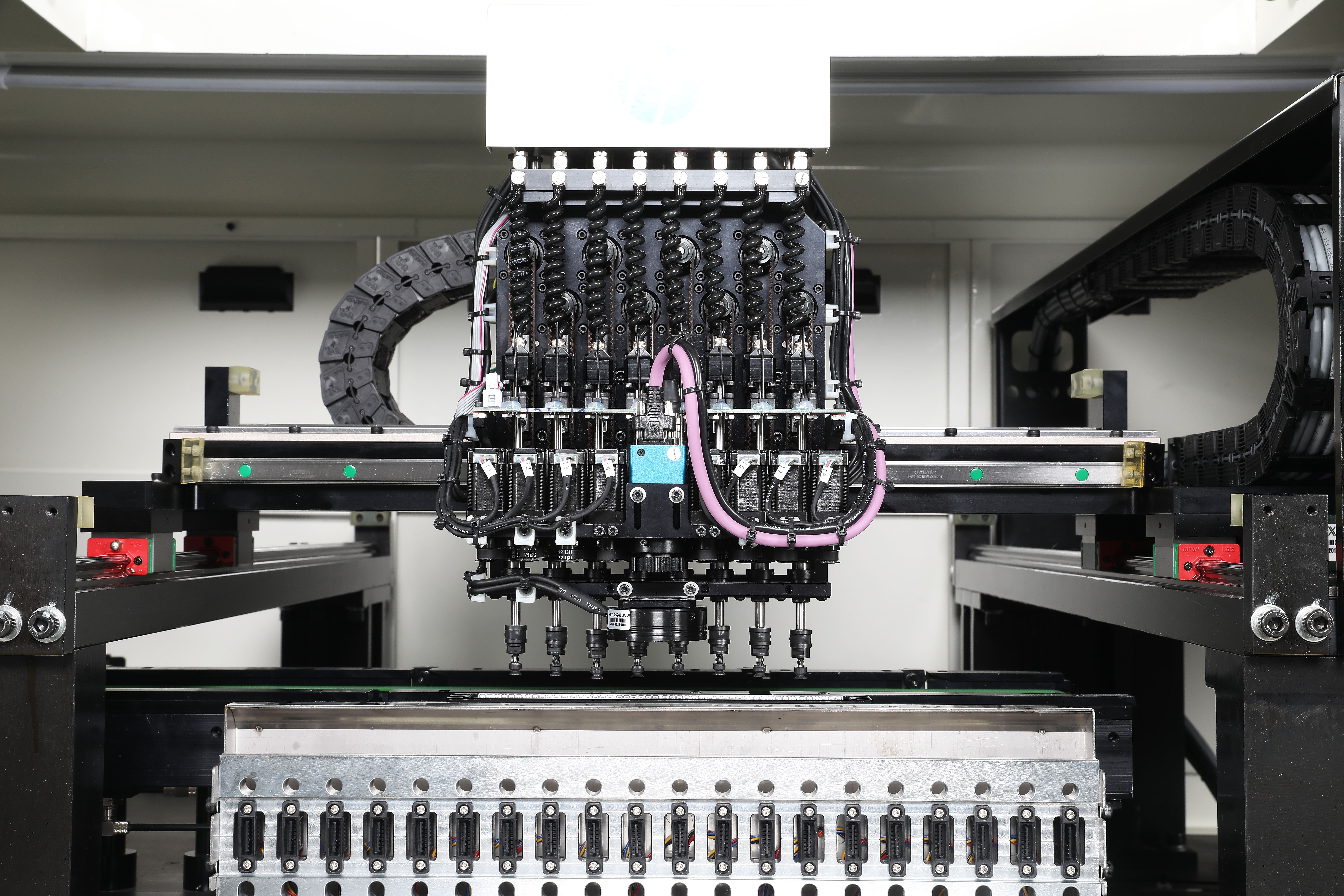

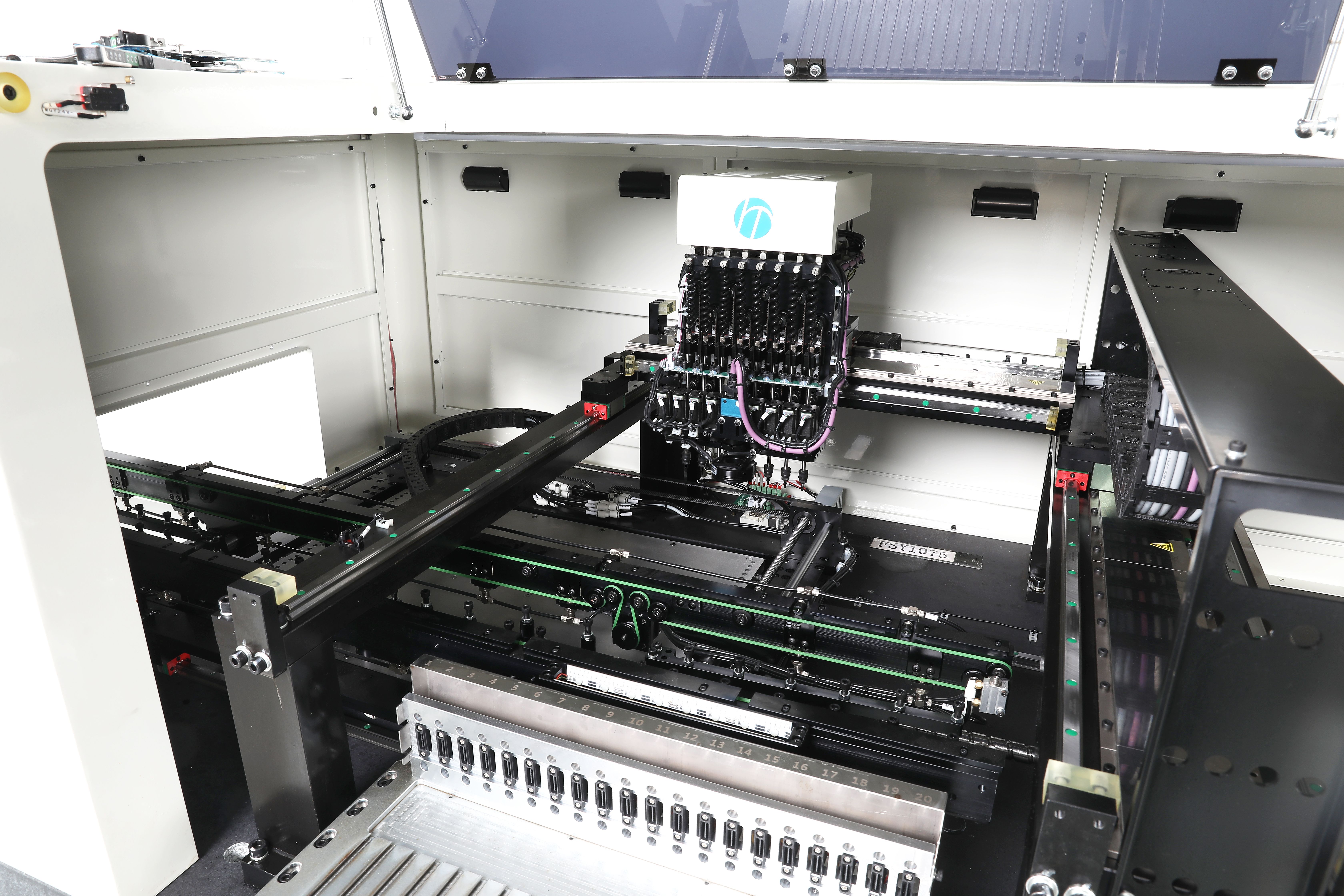

HCT-V8 Automatic Placement Machine for LED Lens Assembly

Surface-mounted components are placed precisely on the PCB using the SMT PCB machine by moving the mount head. based on the components of the PCB SMT machine and the workflow's design concept. PCB mounting devices have been introduced with a variety of features, applications, and quality levels.

China Lens Pick And Place Machine Manufacturer Supplier

HCT specializes in the production of advanced automated equipment for the optical industry.

HCT offers a range of lens pick and place machines designed to handle various types of lenses efficiently. These machines are used primarily in the production processes of optical devices such as cameras, projectors, and microscopes. Lens pick and place machines play a crucial role in ensuring accurate placement and alignment of lenses during assembly.

HCT's lens pick and place machines are known for their precision, speed, and reliability. They are equipped with advanced technology and features such as vision systems for precise positioning, robotic arms for picking and placing lenses, and software integration for seamless operation. These machines are designed to streamline the manufacturing process, reduce errors, and increase productivity.

As a reputable manufacturer and supplier, HCT provides comprehensive support to its customers, including installation, training, and after-sales service. we also offer customization options to meet specific requirements and ensure optimal performance for different applications.

Technical Parameters - Automatic Placement Machine for LED Lens Assembly

|

Model |

HCT-V8 |

|

|

Alignment |

Flying Vision Alignment System |

|

|

Number of Spindles |

8 Spindles x 1 Gantry |

|

|

Placement Speed |

FOR LENS |

18000CPH (Optimum) |

|

For LED |

40000CPH (Optimum) |

|

|

Placement Accuracy |

±0.03mm (Based on the standard chips) |

|

|

Component Range |

Vision Alignment |

For all General lenses (Maximum 15.8MM) |

|

Max Height |

H=12mm |

|

|

Board Dimension(mm) |

Minimum |

50(L) x 50(W) |

|

Maximum |

1,200(L) x460(W) |

|

|

PCB Thickness |

0.5 - 3.0 |

|

|

Board Handling Method |

Inline Conveyor |

|

|

Lens Feeding |

Customized Vibration Tray |

|

|

Tape Feeder |

Feeder Type |

Electric Feeder |

|

Feeder Capacity |

20 (12mm) |

|

|

Utility |

Power |

AC 220V/240V 50/60Hz, Single phase |

|

Max3.2KW |

||

|

Air Consumption |

0.55-0.7MPa (5.6-7.1kgf/cm2) |

|

|

Mass |

Approx.1680kg + 100kg |

|

|

External Dimension(mm) |

2,000(L) x1,150(D) x 1,400(H) |

|

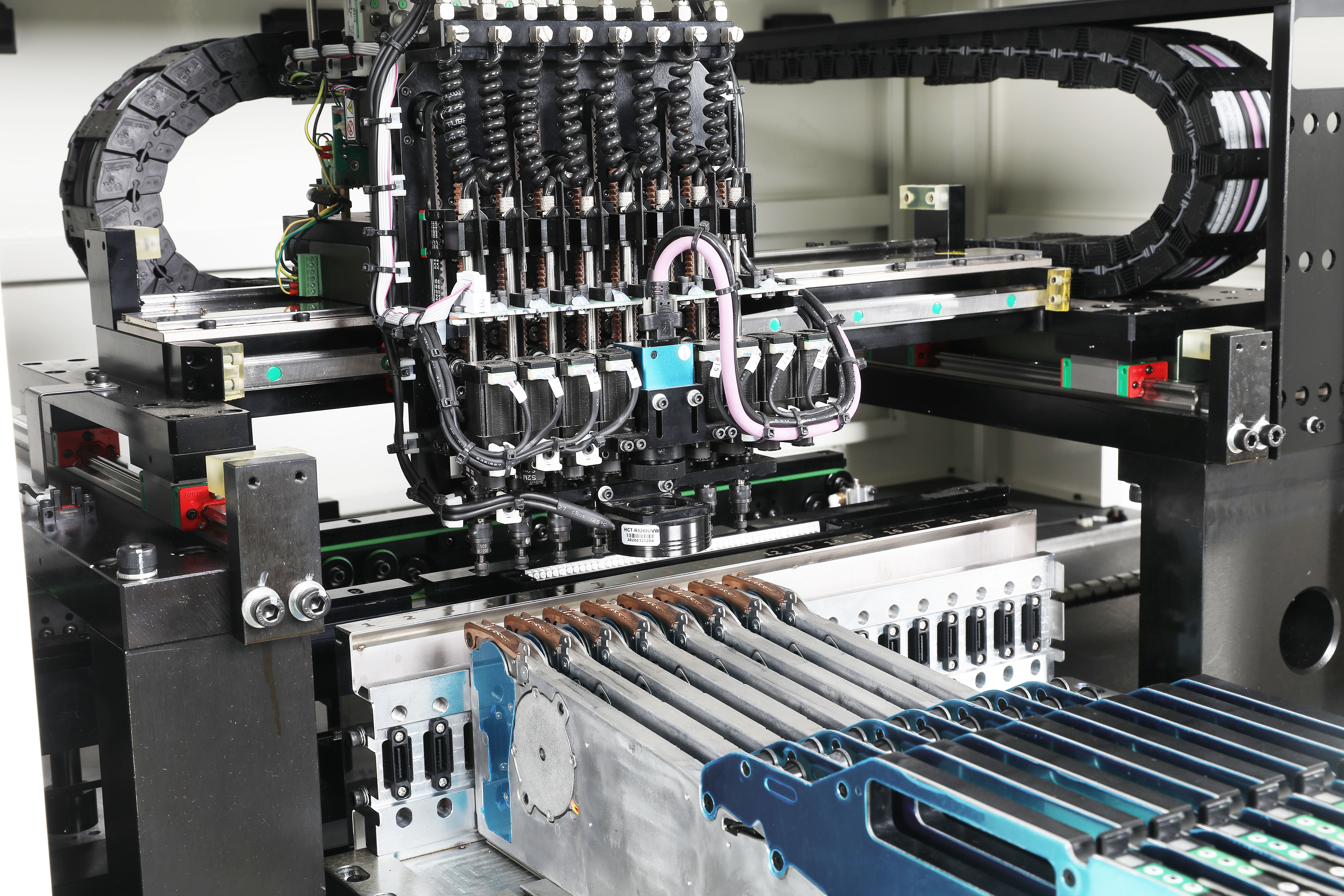

Product Features - Automatic Placement Machine for LED Lens Assembly

1. High-accuracy: Vision On the Fly Alignment to guarantee high accuracy.

With a SMEMA-compatible inline conveyor for line automation.

Specially designed for LED lens assembly.

2. Customization vibration tray for feeding LED Lens.

Can also place SMD components from 0603 to 7474, including resistors, capacitors, high-power LEDs, and standard and irregularly shaped LEDs.

3. Magnetic levitation linear motor (Servotronix) in X and Y axis for high repeatability and stability.

4. Using imported high-precision ball screws, motors, solenoid valves, cables, etc., effectively improves placement accuracy and stability.

5. Self-developed software simplifies production, easy to operate, and programming.

HOW DOES A PICK AND PLACE MACHINE WORK?

First, what is a pick and place machine? An SMT electronics pick and place machine is a robotic assembly device that uses a vacuum to lift a component off a piece of tape, rotates it to the right orientation, then places it on a circuit board, which is also called the circuit board pick and place machine, namely, PCB assembly machine/equipment. It takes a few hours to set up a surface mount pick and place machine to build the assembly, but once everything is running, it works very fast.

The SMT PCB machine is a device that accurately places surface-mounted components on the PCB by moving the mount head. According to the composition of the PCB SMT machine and the design concept of its workflow. People have launched PCB mounting machines with different functions, different uses, and different grades.

Product Display - Automatic Placement Machine for LED Lens Assembly